FLANGES

| Blind Flanges | Lap Joint Flanges | Orifice Flanges | Reducing Flanges |

| Slip-on Flanges | Threaded Flanges | Weldneck Flanges | Large size Flanges |

| Socket weld Flanges | Spectacle Blind | Pipe Flange Gaskets |

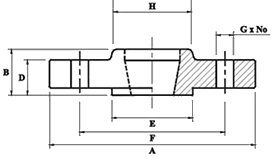

THREADED FLANGES

Threaded Flanges are confined to special applications. Their chief merit lies in the fact that they can be assembled without welding this explains their use in extremely high pressure services, particularly at or near atmospheric temperature, when alloy steel is essential for strength and where the necessary post weld heat treatment is impractical. Threaded Flanges are unsuited for conditions involving temperature or bending stresses of any magnitude, particularly under cyclic conditions, where leakage through the threads may occur in relatively few cycles of heating or stress; sea welding is sometimes employed to overcome this, but cannot be considered as entirely satisfaction.

Key Features:

Can be attached to the pipe without welding (sometimes an additional seal weld is

used as well)

Ideal for higher pressure and temperature applications for small pipe sizes

Not recommended for larger loads, especially when subjected to higher torque

Uses of threaded flanges:

Threaded flanges can be fitted to pipes of various sizes without

welding and this is one chief benefit for which these flanges are highly

demanded.

Threaded flanges can be fitted to pipes of various sizes without

welding and this is one chief benefit for which these flanges are highly

demanded.

They can be used in extremely high pressure applications, particularly at or near

atmospheric temperature, where the necessary post weld heat treatment is not

possible.

They are ideal for small diameter piping applications.

They are economical and time saving devices.

These threaded flanges are normally designed for non-cyclic applications.

The flanges are suitable to be used in applications where welding is

hazardous.

They can be used in highly explosive areas.