FLANGES

| Blind Flanges | Lap Joint Flanges | Orifice Flanges | Reducing Flanges |

| Slip-on Flanges | Threaded Flanges | Weldneck Flanges | Large size Flanges |

| Socket weld Flanges | Spectacle Blind | Pipe Flange Gaskets |

PIPE FLANGES

As the mainstay of our

business, we are dedicated to providing our customers with all possible options of flanges in a wide

variety of steel, chrome, and nickel alloys.

As the mainstay of our

business, we are dedicated to providing our customers with all possible options of flanges in a wide

variety of steel, chrome, and nickel alloys.

Pipe Flanges are widely used as a popular category of pipe fittings. A flange is used to mechanically

connect two pipes together. It can also be used to mechanically connect a pipe to a tee, valve, choke

or any other piece of equipment. Flanges are available in round, square, and rectangular shapes. In

some cases, flanges are usually in the shape of a ring or a plate to form a rim at the end of a pipe

when fastened to the pipe. This is an example of closet flange.

A flange can also be a plate for covering or closing the end of a pipe. This is a blind flange. Thus,

flanges are considered to be projecting or internal components which are used to support mechanical

parts. They are like rims which are used to strengthen the mechanical part or they are a means of

attaching that part to another part or surface.

Uses of pipe flanges:

Flanges are used for variety of purposes. The main purpose is to connect pipes but they are also used

for connecting other equipments. Flanges are fit to a variety of other components besides pipes. They

are fitted to bellows, ducts, wheels, and cameras. We give below the various uses of pipe

flanges:

Flanges are also placed on beams to provide additional strength.

They prevent the beam from failing.

They are used for guide, as the flange of a train wheel.

Flanges are used for attachment to another object like for example, the flange on the end of a pipe,

steam cylinder, etc.

They are fixed on the lens mount of a camera.

A flanged rail is a type of rail with a flange on one side to keep wheels from running off.

Designs of flanges:

Butt weld, Socket weld, Captive, Split, Square, Round, Rectangle etc.

Material grades:

Low Temperature Steel: A350 LF2, LF3, LF6

Nickel Alloys: 200, 400, K500, 600, 625, 800, 825

Stainless Steel: A182 F304/L, F310, F316/L, F316Ti, F321/H, F347/H, F410, F440, 904L

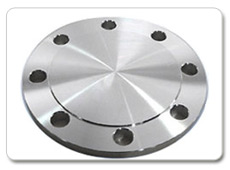

BLIND FLANGES

The blind flange is used to close ends of piping systems. It is a kind of round plate

with no center hold but with all the proper bolt holes. This blind flange is available in various

sizes and materials and is used to provide positive closer on the ends of pipes, valves or equipment

nozzles. This flange helps in easy access to a line once it has been sealed. The blind flange is

sometimes custom made or machined to accept a nominal sized pipe to which reduction is being made.

This reduction can be a threaded reduction or welded reduction.

The blind flange is used to close ends of piping systems. It is a kind of round plate

with no center hold but with all the proper bolt holes. This blind flange is available in various

sizes and materials and is used to provide positive closer on the ends of pipes, valves or equipment

nozzles. This flange helps in easy access to a line once it has been sealed. The blind flange is

sometimes custom made or machined to accept a nominal sized pipe to which reduction is being made.

This reduction can be a threaded reduction or welded reduction.

Grades :

F304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904L Duplex stainless steel

UNS S31803, 2205, Super Duplex stainless steel UNS S32750

Class:

Class 150, Class 300, Class 400, Class 600, Class 900, Class 1500

Features of blind flanges:

Some important features of blind flanges are as follows:

Blind flanges are sometimes supplied with NPT fittings which allow pressure test connections to be

fitted.

They are used to blank off the ends of pipe.

They are also used to blank off the ends of valves and pressure vessel opening.

Considering factors like internal pressure and bolt loading, blind flanges, especially in the larger

sizes, are the most highly stressed of all types of flanges.

Since the maximum stresses in a blind flange are bending stresses at the center, they can safely be

allowed to be higher than in other types of flanges

Blind flanges are made to fit standard pipes in all sizes..

Notes :

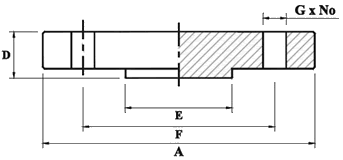

Flange dimensions to ANSI to B16.5.

Dimensions "D" includes raised face thickness.

Larger outlet sizes available on applications.

ANSI 150# / 300# 2mm Raised Face.

ANSI 600# / 2500# 7mm Raised Face.