FLANGES

| Blind Flanges | Lap Joint Flanges | Orifice Flanges | Reducing Flanges |

| Slip-on Flanges | Threaded Flanges | Weldneck Flanges | Large size Flanges |

| Socket weld Flanges | Spectacle Blind | Pipe Flange Gaskets |

SPECTACLE BLIND FLANGES

Separating one part of a line from another requires a spectacle blind, able to switch from closed to open and back again. Bleed rings provide a means to release pressure from the pipe through a controlled opening.

Materials used:

Stainless Steel:

ASTM A182 F304/304L, F316/316L, F316H,F316Ti,F321,F44(UNS S31254)

Key Features:

Can be attached to the pipe without welding (sometimes an

additional seal weld is used as well) Ideal for higher pressure and temperature

applications for small pipe sizes

Can be attached to the pipe without welding (sometimes an

additional seal weld is used as well) Ideal for higher pressure and temperature

applications for small pipe sizes

Not recommended for larger loads, especially when subjected to higher torque

Uses of threaded flanges:

Threaded flanges can be fitted to pipes of various sizes without welding and this is

one chief benefit for which these flanges are highly demanded.

They can be used in extremely high pressure applications, particularly at or near

atmospheric temperature, where the necessary post weld heat treatment is not

possible.

They are ideal for small diameter piping applications.

They are economical and time saving devices.

These threaded flanges are normally designed for non-cyclic applications.

The flanges are suitable to be used in applications where welding is

hazardous.

They can be used in highly explosive areas.

These types of flanges are made from plate, and come in 3 different types.

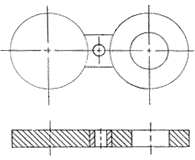

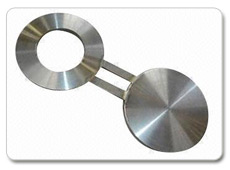

The first and most widely used type are spec blinds – short for spectacle: these are flanges with two equal outside diameter (OD) parts welded together by way of a ‘bridge’. One of the parts also contains an inside diameter (ID), while the other is a blank, or blind. A whole is put at the halfway mark of the bridge. These are also called spectacles, figure 8’s, and figure 8 blanks, because of their resemblance to reading glasses (spectacles) and figure 8’s. These are referred to as ‘Line Blanks’ in the ASME/ANSI standards.

The second and third types are quite similar: both have longer bridges, referred to as ‘paddles’, which resemble longer handles. One type has only an OD, and so is a blind plate – similar in appearance to a large pizza oven peel. These are referred to as paddle blinds. The other type is exactly the same but comes with an ID as well, enabling flow-through when installed in a piping system. These pieces have holes in the paddle which enables field personnel to determine by sight which piece is installed in a system. These are referred to as paddle spacers, and are often supplied in sets together with the paddle blinds.

All 3 types of these flanges are used in piping systems or pressure vessels where the flow needs to be interrupted from time to time. They are installed between two pipe flanges (as specified above), and by way of a screw inserted into the hole in the bridge or paddle, they are able to rotate or ‘swing’ into and out of position to interrupt or allow the flow, as the user sees fit.